In-Mould Cutting Thermoforming Machine, DB-3021

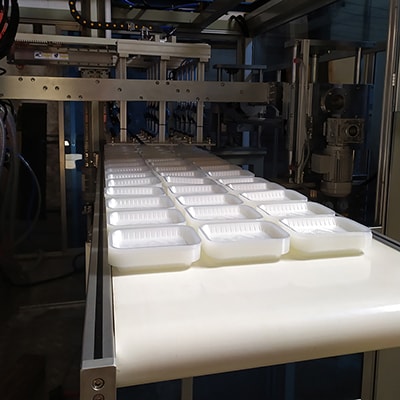

Thermoforming machine for making plastic trays, plates, bowls and lids

In-Mould Cutting Thermoforming Machine, DB-3021

Thermoforming machine for making plastic trays, plates, bowls and lids

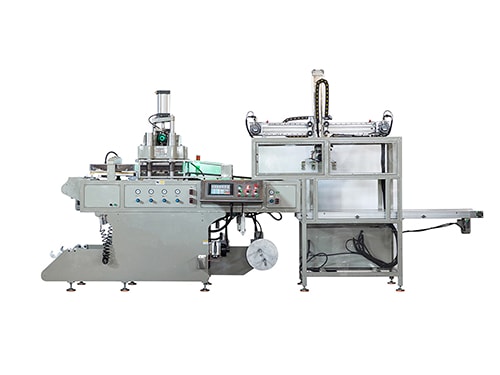

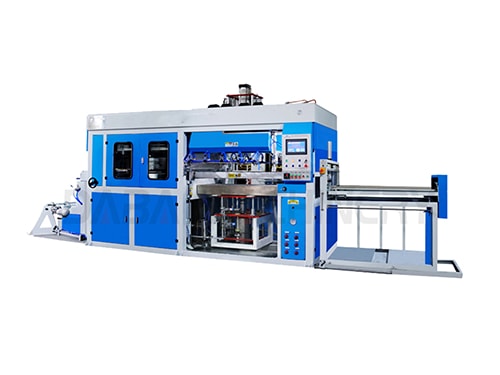

Boost your production efficiency with the in-mould cutting thermoforming machine. This advanced machine is controlled by a micro PLC for high production efficiency, reaching up to 1500 cycles per hour. Featuring a human-machine interface (HMI), it seamlessly integrates heating, forming, cutting, and stacking into one streamlined process. Perfect for transforming BOPS, HIPS, PS, PVC, PET, and PP plastic sheets into trays, plates, bowls, lids, and more. Get in touch today to see how the in-mould cutting thermoforming machine can enhance your operations.

Ideal for producing various boxes, plates, trays, bowls, and lids from BOPS, HIPS, PS, PVC, PET, and PP plastic sheets.

| Model | DB-3021 | |

| Max. forming area (L×W) | 760×540mm | |

| Max. forming depth | 100 mm (pick product from inside the mould) | |

| 120 mm (pick product from outside the mould) | ||

| Sheet thickness | 0.2-1.5 mm | |

| Production capacity | 600-1500 cycle/hour | |

| Heating power | 180 kW | |

| Heating area | 3010×790 mm | |

| Motor power | 29 kW | |

| Air pressure | 0.7 MPa | |

| Air consumption | 3500 L/min | |

| Water consumption | 70 liter/min | |

| Power supply | Tri-phase, AC 380±15V, 50HZ | |

| Sheet roll diameter | 1000mm | |

| Weight | 10000kg | |

| Dimensions (L×W×H) | Main Machine | 7550×2122×2410mm |

| Feeder | 1500×1420×1450mm | |

- Multi-zone infrared dual heating and positive-negative thermoforming system

- Equipped with servo-assisted drive system and dual stacking robot system for stable and precise stacking

- Equipped with a fault diagnosis system and advanced in-mold cutting technology, enabling zero-error trimming of products.

- Three operation modes: manual, semi-automatic, and fully automatic

- Sheet transport system driven by a servo motor

- Remote control and memory storage capabilities