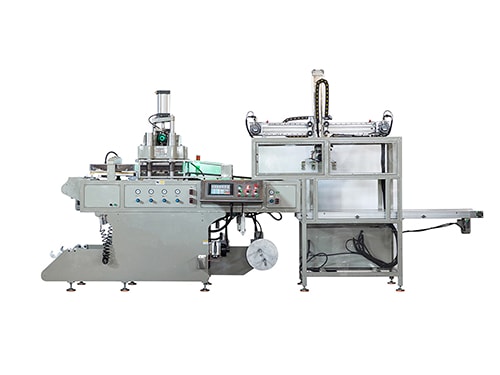

Plastic Vacuum Forming Machine, DB-720/1220

Vacuum former for making plastic packaging containers

Plastic Vacuum Forming Machine, DB-720/1220

Vacuum former for making plastic packaging containers

Expand your packaging production capabilities with the plastic vacuum forming machine. This efficient system handles PP, APET, PVC, HIPS, PS, PET, and PE sheets, perfect for manufacturing boxes, trays, fast-food containers, plates, lids, biscuit trays, egg trays, mobile phone trays, and various blister packs.

PP, APET, PVC, HIPS, PS, PET, and PE sheets

Ideal for creating boxes, trays, fast-food containers, plates, lids, biscuit trays, egg trays, phone trays, and other blister packaging.

Contact us today to find out how this vacuum forming machine can enhance your plastic packaging production.

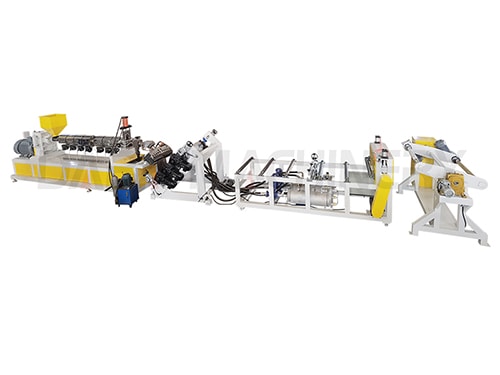

| Max. forming area | 720×1220mm |

| Forming depth | 0-165mm |

| Production capacity | 200-600 times/hour |

| Sheet thickness | 0.1-2mm |

| Forming times | 1 or 2 times |

| Oven power | 30kW |

| Vacuum pump power | 3.0kW |

| Power supply | 380V 50Hz 3P |

| Dimensions (L×W×H) | 8800×1500×2500mm |

| Weight | 3000kg |

| Flow rate | 100cm³/min |

- Entire production process is PLC-controlled, integrating seamlessly with modern computing systems.

- Vertical cylinder sheet pulling design ensures rapid forming, reducing processing time, saving energy, and guaranteeing consistent product quality.

- Infrared ceramic heaters with individual temperature regulators provide precise heat control, achieving over 50% energy savings compared to traditional heaters.

- Enclosed furnace heating chamber offers uniform heating and minimal heat loss. Includes manual switch for easy vertical adjustment, enhancing operational control and consistency.

- Equipped with air cooling, water cooling, and high-speed cold water spray systems to accelerate forming speed and maintain superior product quality.