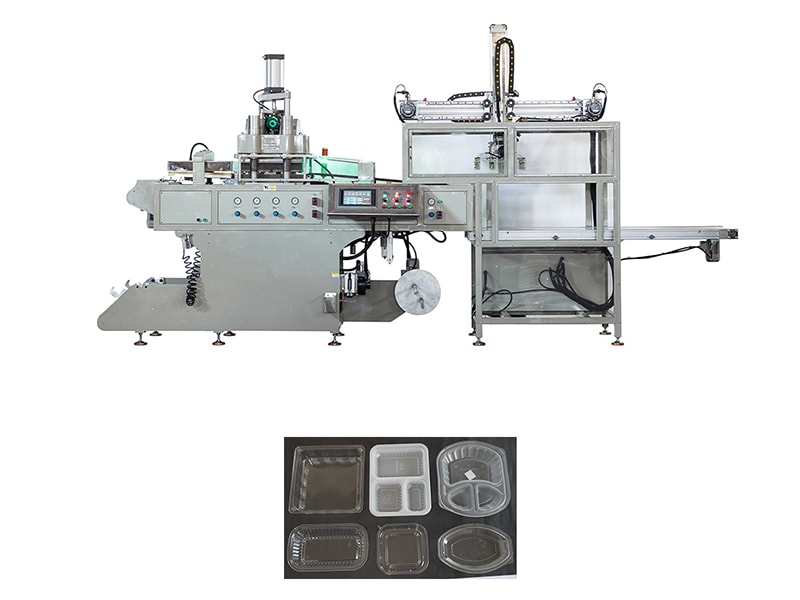

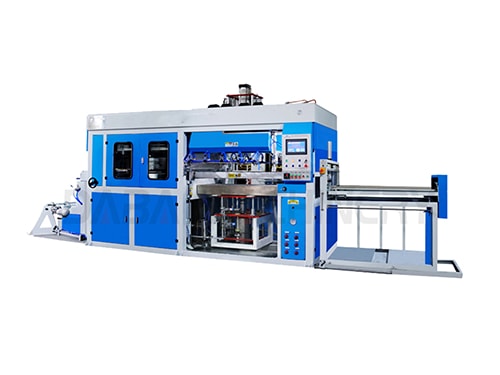

BOPS Plastic Thermoforming Machine, DB-5162/5476/6378/7095

Thermoforming machine for making plastic packaging containers

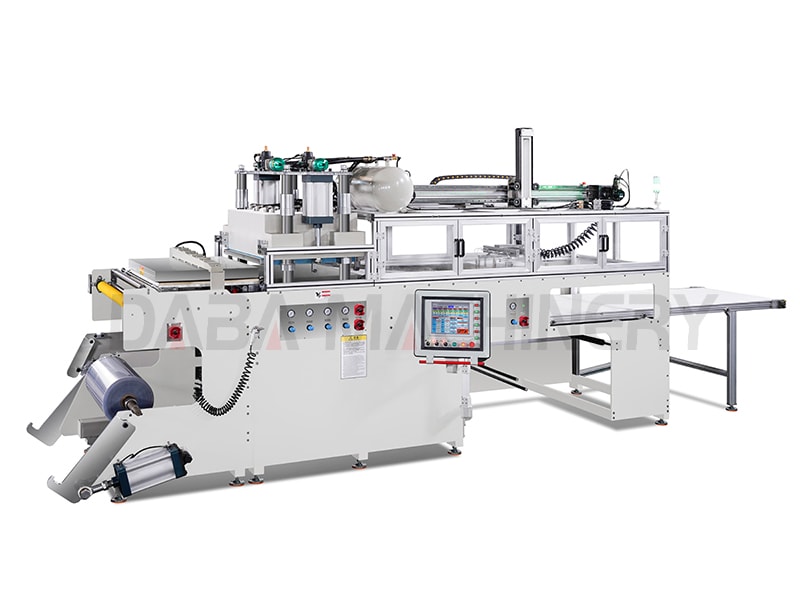

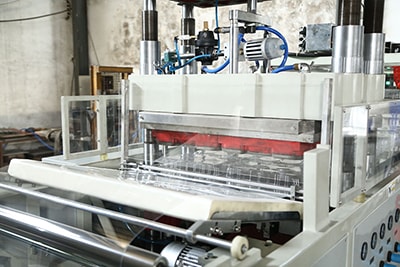

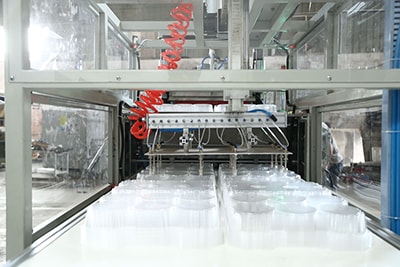

This series of plastic thermoforming machines is composed of mechanical, electrical, and pneumatic components. The entire system is controlled by a micro PLC, allowing for human-machine interface operation. It integrates feeding, heating, forming, cutting, and stacking into one seamless process.

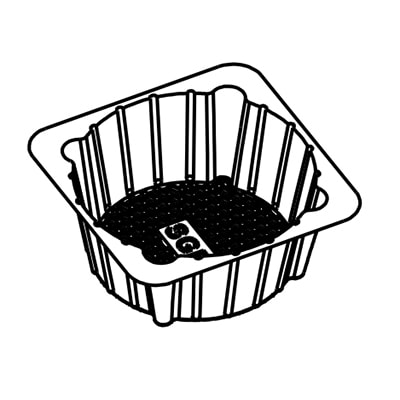

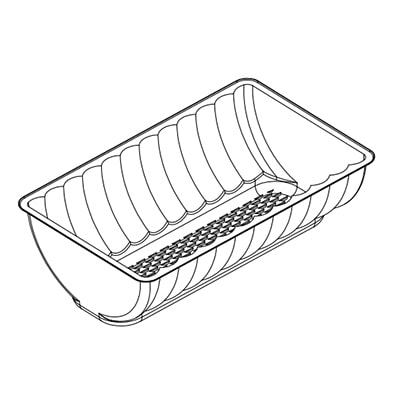

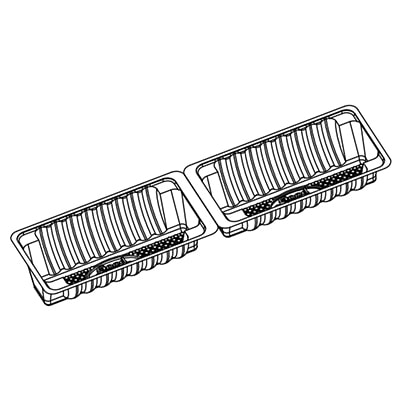

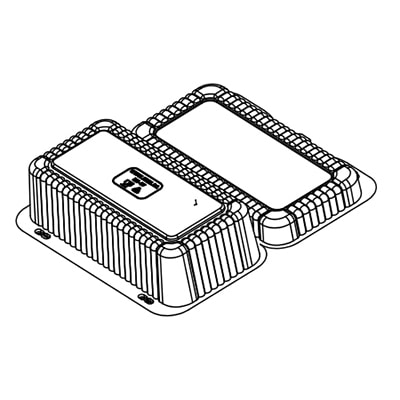

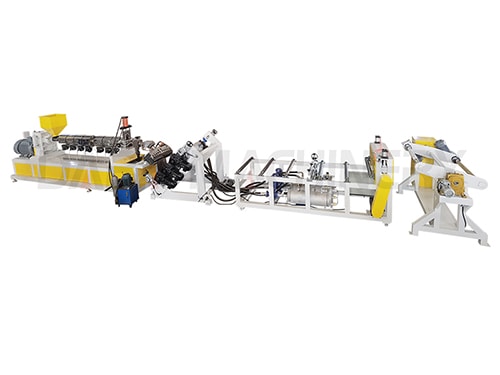

Suitable for BOPS, PS, APET, PVC, and PLA plastic sheeting rolls, this plastic thermoforming machine is ideal for producing a wide range of lids, plates, trays, and clamshell containers. Typical applications include lunch box lids, sushi boxes, paper bowl lids, aluminum foil lids, mooncake trays, pastry trays, food service trays, supermarket display trays, oral liquid packaging, and pharmaceutical injection trays.

| Model | DB-5162 | DB-5476 | DB-6378 | DB-7095 |

| Max. forming area | 510×620mm | 540×760mm | 630×780mm | 700×950mm |

| Max. forming depth | 100mm | 120mm | 125mm | 125mm |

| Total trimming knife length | APET:6000mm PVC PLA:7000mm OPS:10000mm | APET:9000mm PVC PLA:10000mm OPS:13000mm | APET:9000mm OPS:13000mm | APET:12000mm OPS:18000mm |

| Sheet thickness | 0.10-1.0mm | 0.10-1.0mm | 0.12-1.0mm | 0.15-1.0mm |

| Air pressure | 0.7Mpa | 0.7Mpa | 0.7Mpa | 0.7Mpa |

| Air consumption | 1500 L/min | 1800 L/min | 2000 L/min | 2400 L/min |

| Water consumption | 5 L/min | 6 L/min | 8 L/min | 15 L/min |

| Power consumption | 7.5kW/h (approx.) | 9kW/h (approx.) | 10kW/h (approx.) | 14kW/h (approx.) |

| Heating power | 24kW | 30kW | 40kW | 50kW |

| Motor power | 8kW | 9kW | 9kW | 12kW |

| Power supply | AC 380V±15V 50/60HZ | AC 380V±15V 50/60HZ | AC 380V±15V 50/60HZ | AC 380V±15V 50/60HZ |

| Production capacity | 600-1200 cycle/h | 600-1200 cycle/h | 600-1200 cycle/h | 600-1400 cycle/h |

| Max. sheet roll diameter | 710mm | 710mm | 800mm | 1000mm |

| Max. sheet roll width | 680mm | 810mm | 810mm | 1000mm |

| Dimensions | Machine: 2950×1550×2350mm Stacker: 2670×960×2350mm | 5000×1750×2500mm | 5600×1750×2500mm | 6590×1760×2720mm |

| Weight | 3500kg | 4800kg | 5200kg | 7000kg |

- Servo-driven system for smooth motion, high efficiency, and energy savings.

- Built-in memory storage system for quick access and data retention.

- Multiple selectable operating modes for versatile production needs.

- Intelligent diagnostic analysis for quick troubleshooting and optimized performance.

- Quick-change mold air baffles for efficient setup and reduced downtime.

- In-mold cutting ensures consistent and precise trimming.

- Low energy consumption with high utilization rates, maximizing production efficiency.

- Machine supports 180-degree rotation and offset stacking for flexible arrangement.

- Low failure rate for reliable and continuous operation.